Digital Transformation is at the center of most manufacturing companies’ strategies.

Digital technology has changed and will continue to alter the landscape of business, engineering, and manufacturing. Digital business drivers are changing due to shifting requirements for designing, producing and servicing products. The past few years have seen significant change, the pace and scale of change continue to impact most organizations through information overload.

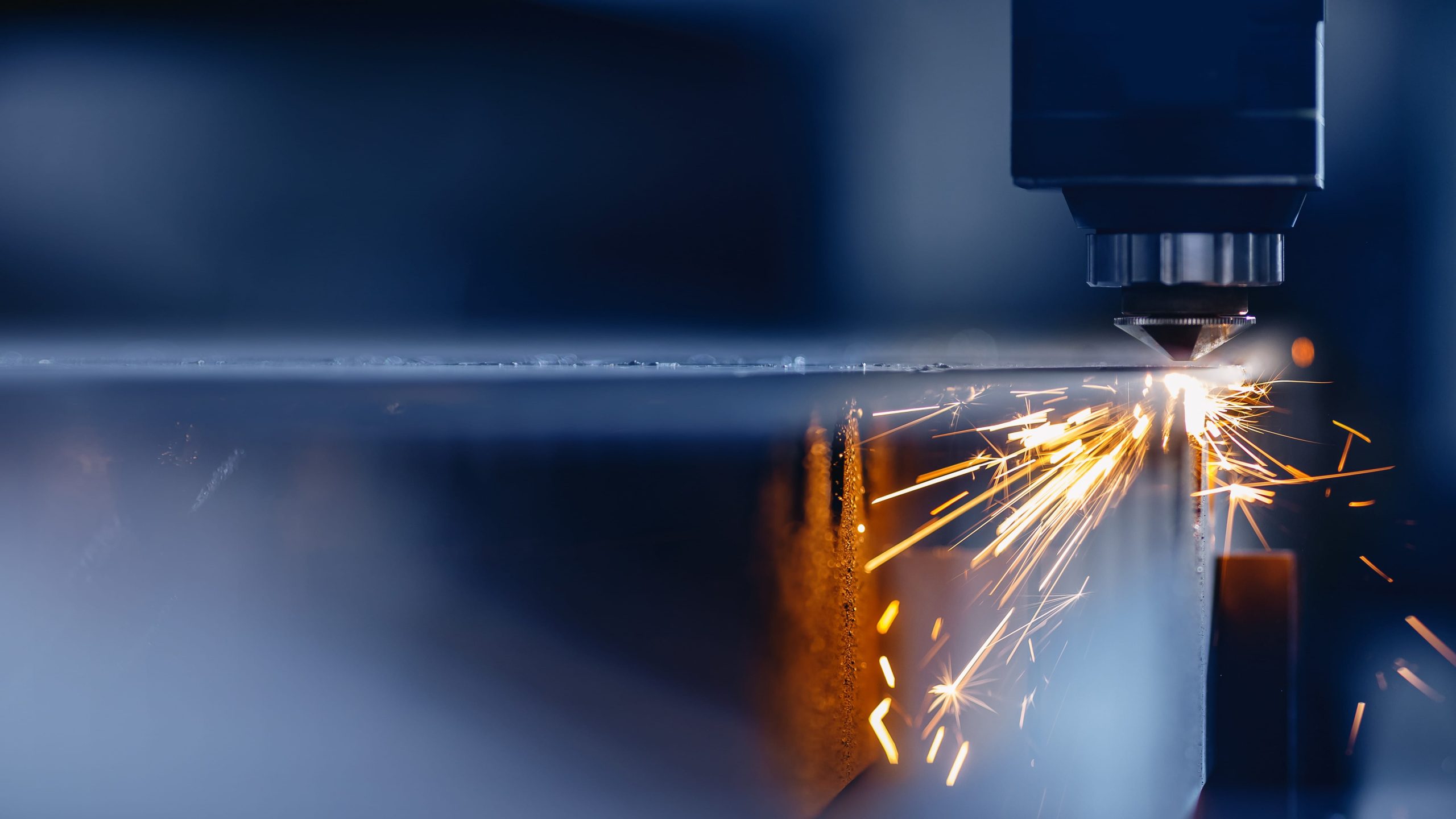

There are numerous glamorous examples of how new technologies transform or disrupt different industries – for example, autonomous cars in the transport industries, 3D printing in manufacturing, and robotics in logistics. Other key innovation accelerators include internet of things, virtual and augmented reality.

Don’t confuse activity for progress.

Time is valuable and your team is busier than ever. But information workers are wasting so much time searching, sharing, moving and managing information, due to the above-mentioned information overload. Actify recognizes that while most organizations use digital technologies, few actually reap their full potential. We want to provide clarity to the ever-changing landscape of product data management, enterprise CAD and business intelligence solutions to enable discrete manufacturing organizations to get the most out of their data and start to really play in the now!

90% of the data that exists today was created in the last 2 years. Is your business ready to handle that level of data?

Actify address ways to handle the magnitude of this combined data and the relationships between disparate and dispersed data at production and all the way back to the product definition. Learn how leveraging historic data and insights gained from legacy projects can deliver best practices across departments and their extended enterprise to impact the bottom line.

There has been a trend towards ‘unbundling’ technology applications.

For companies to better leverage their existing investments and gain more value from their line-of-business systems, it is essential to establish an architecture that unites these ‘best of breed systems’. A platform for managing and orchestrating multiple sources of data that supports and optimizes business processes to ensure optimal business-IT alignment. Learn how to eliminate information silos. Actify Centro provides a powerful platform for discrete manufacturers to integrate many line-of-business systems and deliver a centralized and unified view of their product data.

Today’s business intelligence solutions do not understand product data.

Actify defines its technology as (PDI) Product Data Intelligence. Because today’s business intelligence solutions do not understand product data or handle the types of files or information that are synonymous with engineering and manufacturing organizations. Discrete manufacturers data is unique because your information assets include 3D models and 2D drawings with information hidden within CAD files (dimensions, eBOM, PMI, GD&T, etc.) Your data no longer needs to be a static source of knowledge, but a source of concurrent insight coming from across the enterprise.